Styrene plastic is a go to machinable plastic when high impact resistance and machinability are needed at a cost effective price point.

How to thermoform polystyrene plastic sheets.

Simply stated vacuum forming is the process of taking a flat sheet of plastic and changing it into a contoured shape.

Prototypes packaging soap and candle molds scale models theater props abs thermoform plastic sheets due to its low cost and superior physical properties abs acrylonitrile butadine styrene is one of the most popular thermoform plastics used for vacuum forming.

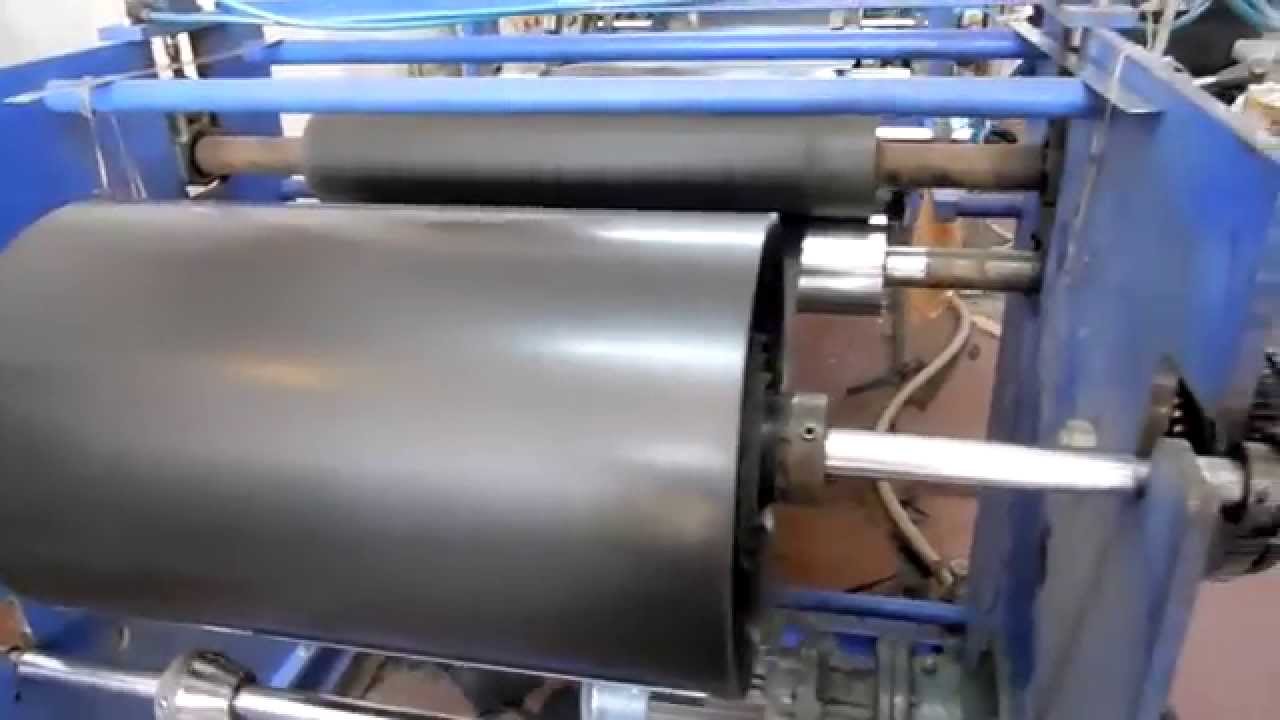

This is accomplished by putting a piece of plastic into some type of clamping mechanism heating the sheet up to a forming temperature stretching the heated sheet of plastic over a mold sealing the heated plastic sheet on the.

Once heated hips is highly malleable meaning high impact polystyrene thermoforming is an excellent way to manufacture the plastics our customers need.

Styrene is commonly used in prototypes as it is dimensionally stable and easy to fabricate paint and glue.

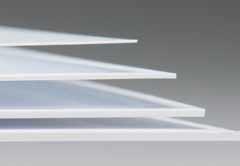

Polystyrene is available in three primary forms including a hard impact resistant plastic a lightweight foam and a thin film.

High impact polystyrene thermoforming.

Made of fda listed material ul 94hb.

Many plastic sheet materials can be shaped by thermoforming.

High clear ps plastic sheets for thermoforming polystyrene find complete details about high clear ps plastic sheets for thermoforming polystyrene polystyrene plactic sheet thermoforming polystyrene from plastic sheets supplier or manufacturer pulixin packaging materials shanghai co ltd.

Easy to form polystyrene sheets and.

Some plastics like hdpe and pp have narrower processing windows and lower melt strength which make them more difficult but not impossible to thermoform.

Recommended uses for styrene thermoform plastic sheets.

Polystyrene is a thermoplastic that s solid at room temperature but will begin to melt at 210 c.

Styrene is also nontoxic and odorless with excellent forming properties.

This gives polystyrene almost the same amount of versatility as polyethylene.

Amorphous plastics like abs and polycarbonate generally have wide processing windows and good melt strength making them easy to thermoform.